AI-Enabled System for Ultrasonic Non-Destructive Testing

About

A global industrial manufacturer needed a more advanced way to check the quality of steel material used in high-precision bearing production. As variability in steel sourcing increased, the company needed a reliable method to examine each component before it went into downstream machining. Even small inclusions or sub-surface defects can lower durability and harm performance, so early detection is crucial for maintaining product reliability.

To stay competitive, the manufacturer sought a smart non-destructive testing approach that could provide real-time, in-line inspection for different types of steel. The solution had to support consistent object detection and quality assurance, while working directly on the production line with fast edge analytics. This shift from statistical sampling to per-piece inspection would provide full traceability and help uphold the company’s long-established quality standards.

Challenge

- Structural quality check. The system had to verify the presence or absence of critical elements and detect any foreign materials on or within each ring.

- High-speed, high-precision inspection. The system should be capable of detecting defects below the surface as small as 0.04 mm and operate within a cycle time close to 1.1 seconds to avoid slowing down the production line.

- 100% inspection goal. The customer needed a system that supports full per-piece inspection today, with a future option for batch inspection using ring tagging to improve throughput without losing traceability.

- Scalability across variants. The system had to adapt to different ring sizes, shapes, and material types, including diversified steel sources and non-metallic materials.

- Consistent inspection across ring states. It needed to work reliably for hardened, polished, and other material conditions.

- Ready for multi-line rollout. The initial setup targeted one line, but the approach had to scale across additional lines and future facilities.

Solution

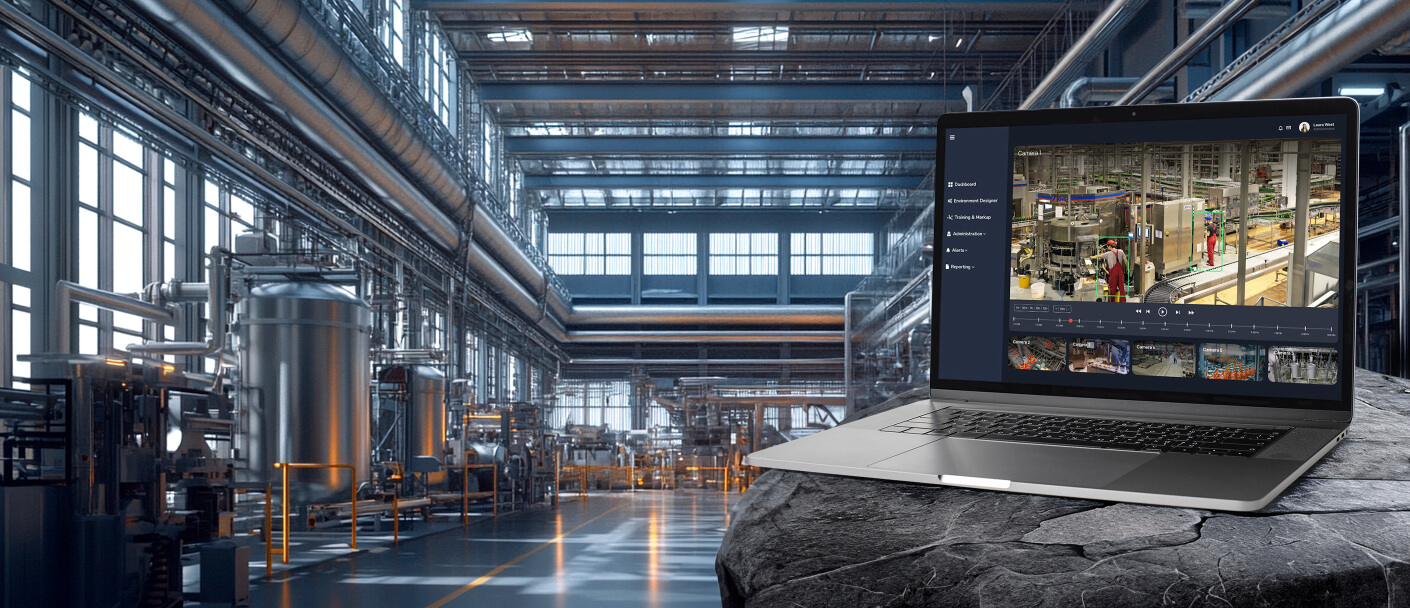

Softarex developed a Proof of Concept for a computer vision-enabled system that supports non-destructive testing of bearing rings. The PoC combined ultrasonic scanning with real-time CV analytics to identify surface and sub-surface defects. It proved to be viable for future in-line deployment, supporting end-to-end inspection workflows.

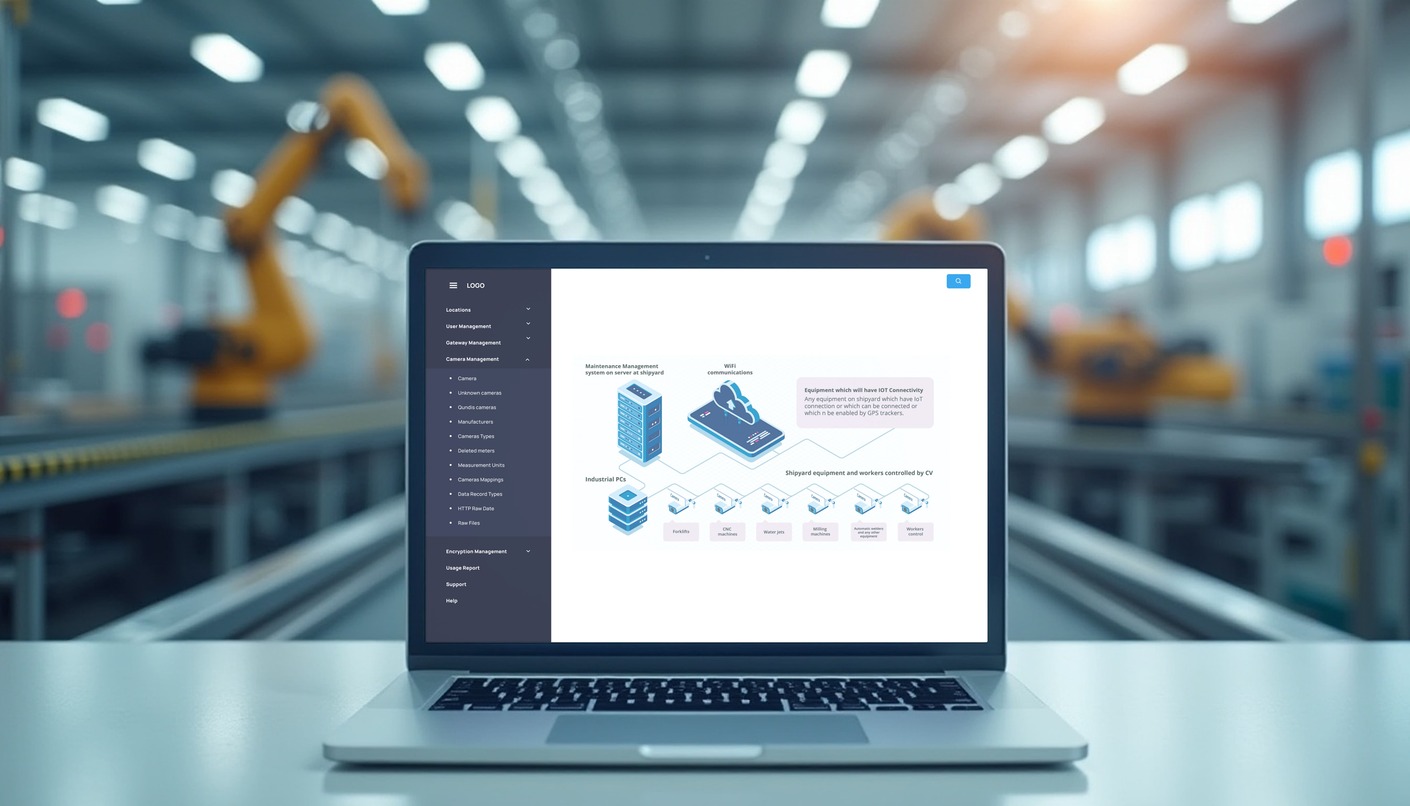

The solution was built as a modular and scalable system:

- Ultrasonic scanning station. A dedicated testing zone was set up at the customer’s facility to capture high-resolution subsurface data for each ring. The setup used high-frequency ultrasonic sensors capable of detecting micro-defects and structural irregularities.

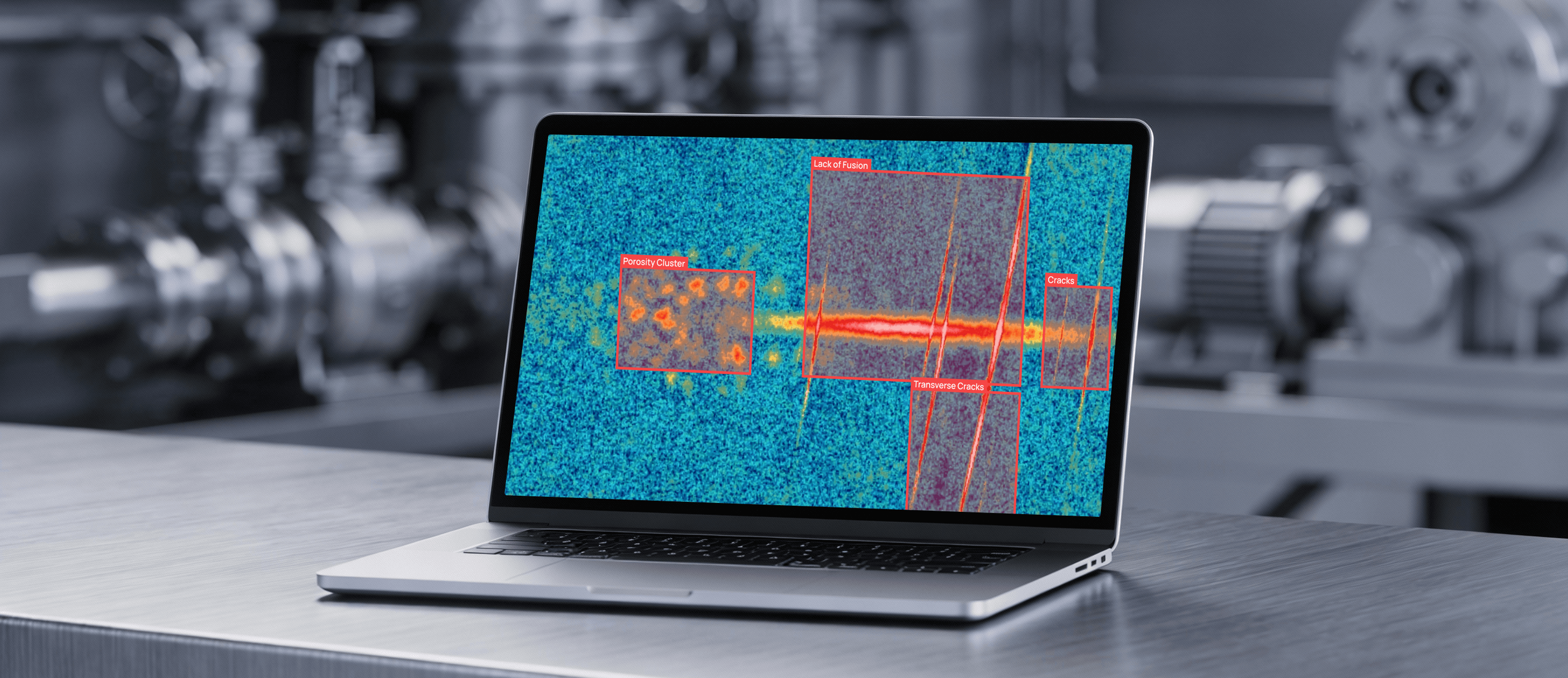

- Computer vision analysis pipeline. The ultrasonic data was processed through a computer vision pipeline that included defect detection, classification, and segmentation. This allowed for accurate identification of defect size, location, and orientation and laid the groundwork for automated quality assessment.

- Edge-ready architecture. The PoC operated as a local web application on a Linux-based server. Its backend components were built in Java and Python, while the interface used ReactJS. This setup made the system suitable for production lines and ready for future cloud integration.

- Data management and traceability. All scans and annotations were stored locally to support traceability, enable audits, and meet future model training needs.

- User interface. Operators accessed a graphical dashboard that displayed inspection results and allowed for review, tagging, and workflow monitoring.

- Scalable system design. Although the PoC ran on a single line, the architecture was ready to expand to multiple production lines and facilities. It also supported future batch-inspection scenarios with ring tagging for higher throughput.

Project results

- The Softarex team developed a production-ready proof of concept that showed the potential of using ultrasonic scanning with computer vision to detect subsurface inclusions as small as 40 μm.

- Verified stable performance across rings with various sizes, shapes, and materials.

- Reached a full scanning cycle of about 1.5 seconds per ring without interrupting the production flow.

- Confirmed accurate detection, localization, and classification of subsurface issues.

- The system allowed full traceability by saving scans, annotations, and defect details for expert review.

- Achieved around 75% non-destructive testing accuracy using synthetic training data, with expectations of over 90% accuracy using real samples.

- Created a clear path to reach 100% accuracy after gathering and labeling data from more than 1,000 defective rings.

Technical challenges

Selected Projects Overview

Get in touch with Softarex’s team

Have questions about your future project? Feel free to contact our team.