Production Monitoring System

Challenge

Production managers need real-time information about all events on the production floor to timely address any emerging manufacturing problems like production line stoppage, unplanned downtime, quality defects in the manufactured products, inadequate efficiency of processes, low productivity, and many others. However, with old equipment, it’s very difficult to get any data out of production lines other than parts produced per hour.

Therefore, there’s an urgent need for industrial monitoring systems that without any modification of the existing equipment would keep track of production areas 24/7 and provide production managers with real-time data on the manufacturing process.

Solution

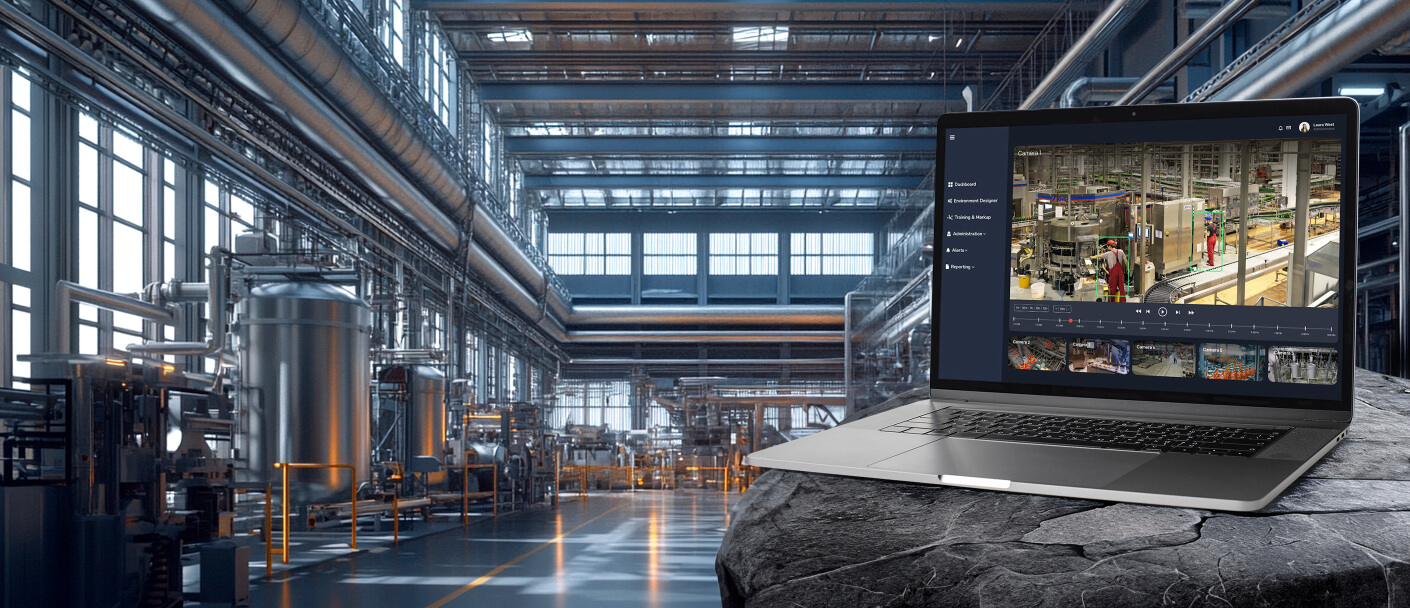

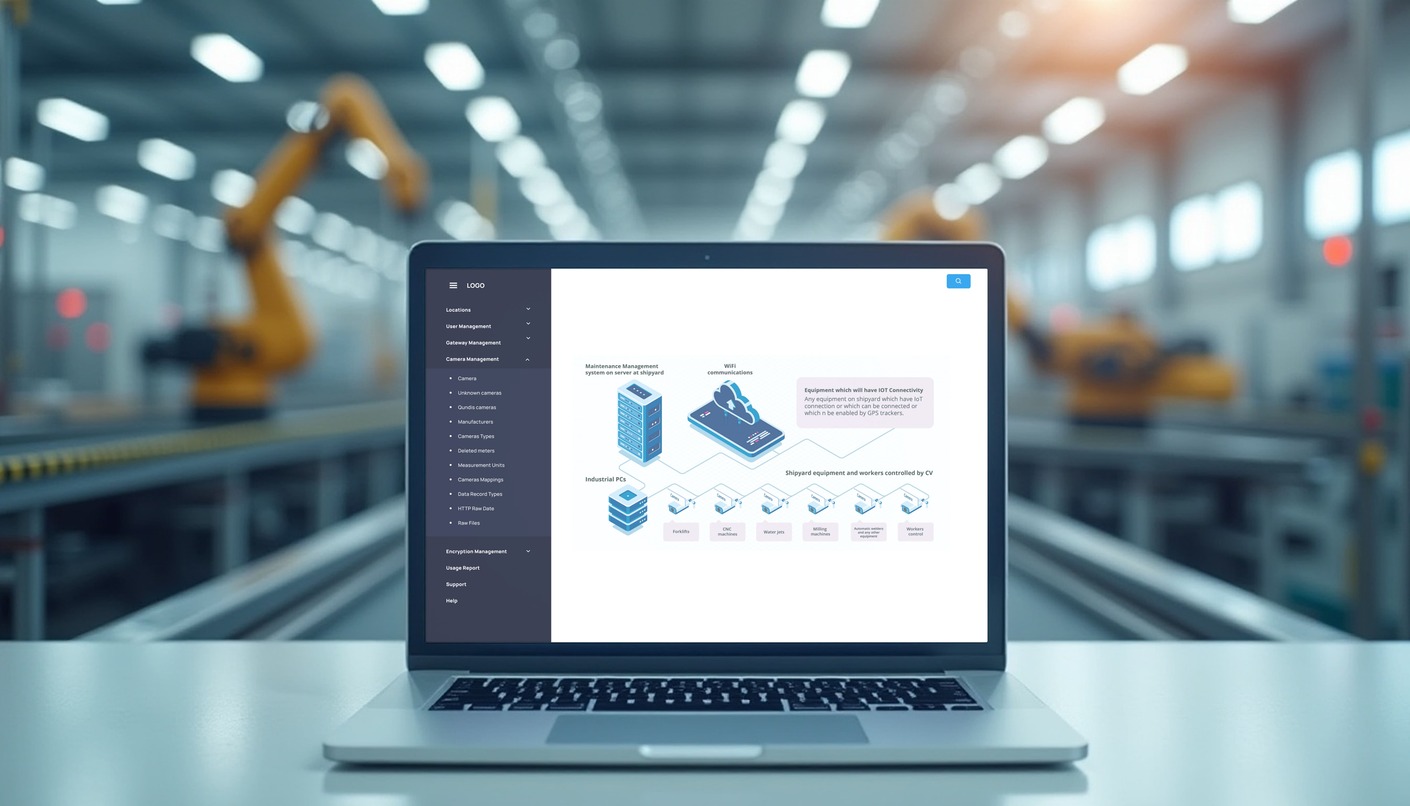

In response to our Customer’s demand, we have developed a custom cloud-based Production Monitoring System powered by computer vision and machine learning. Through cameras, IoT sensors, and devices, the system monitors production areas in real time and collects valuable manufacturing data: defects in the manufactured products, the number of spent materials, cycle time, production line stops, production and non-production times, the number and coordinates of objects on the production line, workers’ movements, and more.

Softarex’s Production Monitoring System has the following features:

- 24/7 production monitoring;

- Real-time automated data collection;

- Access to the obtained data from any electronic device;

- Machinery condition checking;

- Forecasting of workflow failures and possible congestion;

- Quick notifying of any production-related problems: downtime, line stoppage, machine failure, etc.;

- Real-time monitoring and counting objects throughout production lines;

- Measuring the coordinates of necessary fragments or device parts of the specified machines;

- Employee activity control.

Project Results

Production Monitoring System by Softarex has helped our Customer achieve the following:

- Reduced risk of production issues due to timely responding to the emerging alerts;

- Reduced paperwork and human effort;

- Fully automated production line workflow;

- Streamlined production processes;

- Improved production process efficiency;

- Increased workplace safety;

- Enhanced workers’ productivity and motivation thanks to continuous monitoring of their activity;

- Reduced operational costs.

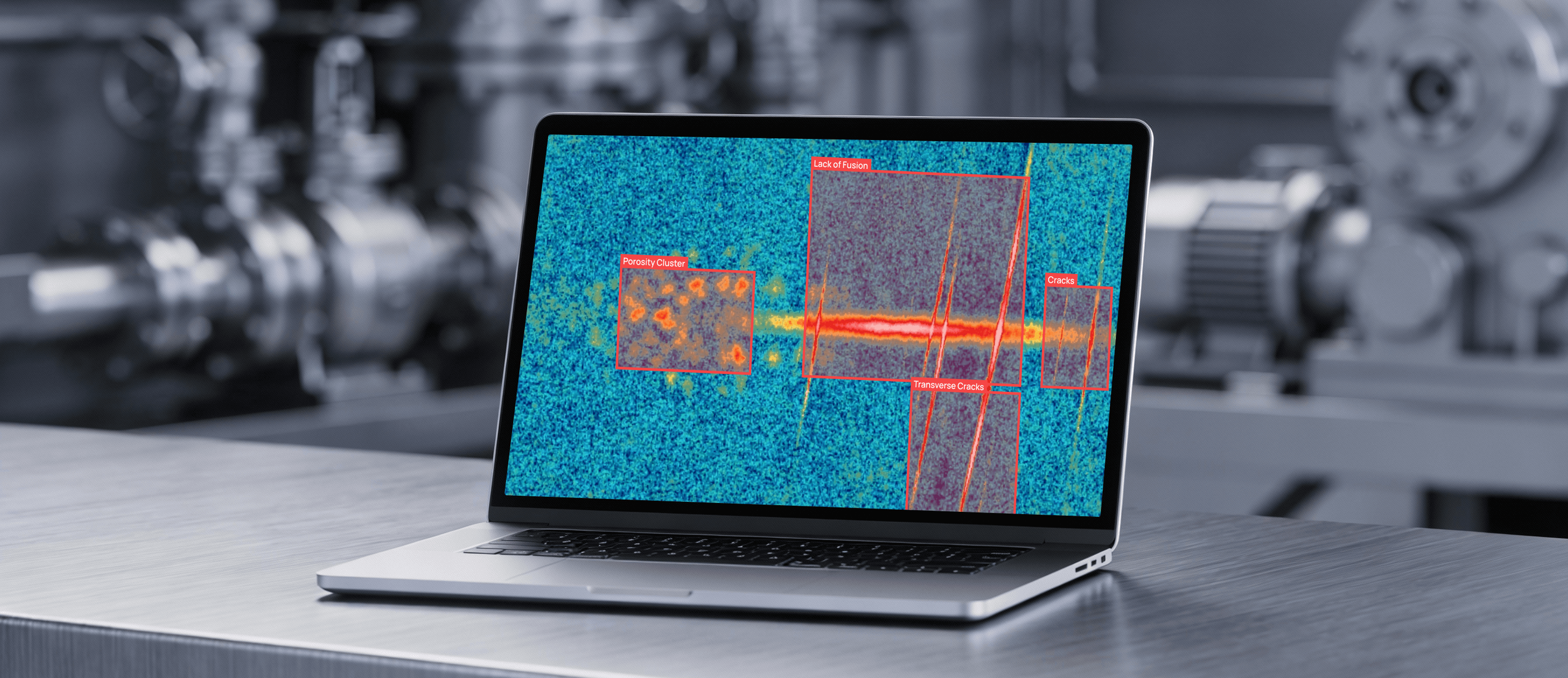

Technical challenges

- Real-time processing of video stream from multiple cameras;

- Development of AI algorithms for building adaptive maintenance plans based on actual utilization;

- Development of approaches for collecting data on various equipment using IoT and CV methods.

Selected Projects Overview

Get in touch with Softarex’s team

Have questions about your future project? Feel free to contact our team.