Real Time Defect Detection System

About

A global leader in bearings and seals manufacturing needed to improve quality control at one of its US production facilities. After more than a century of engineering expertise and operations in 130 countries, the company has built its reputation on providing precision-engineered components that keep the world running. Quality assurance is critical for maintaining this legacy and meeting the performance standards that industrial clients around the globe rely on.

To strengthen their quality control abilities and stay at the forefront of the industry, the company looked for an intelligent inspection system that could detect complex surface defects across different product lines without needing extensive reconfiguration.

Challenge

- Defect detection complexity. The system had to consistently identify different surface defects, such as scratches, smears, discolorations, rust spots, chips, and scrapes, regardless of their orientation, size, or location on bearing components ranging from 35mm to 150mm in diameter.

- Multi-surface inspection. It needed to detect imperfections across various surface types, including flat surfaces, curved surfaces, and internal diameters. Each type presented unique inspection challenges.

- Operational reliability. The existing solution was unreliable in production and required significant manpower for updates and staff retraining. The new system needed to reduce this burden.

- Low-touch configuration. The customer needed a method that did not require frequent CV model adjustments or lengthy setup for each new product family.

Solution

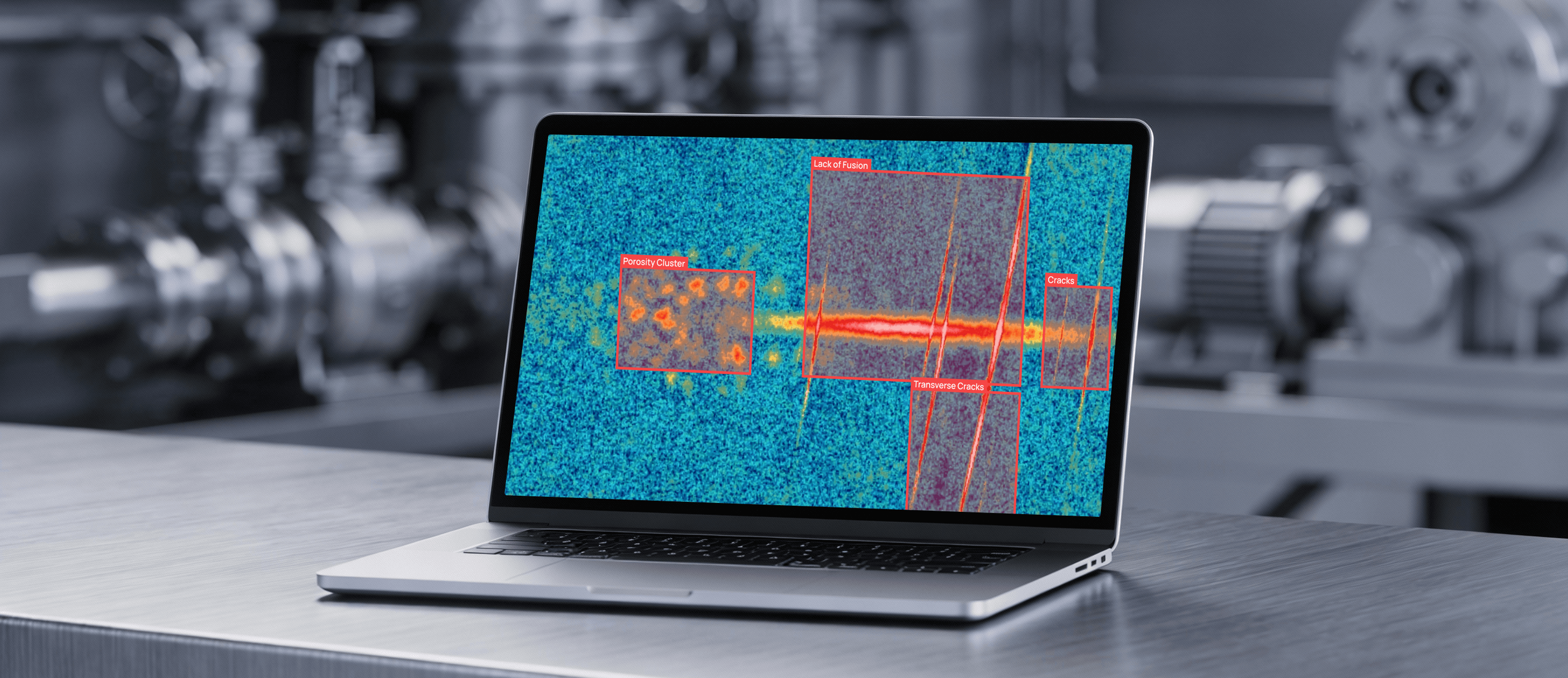

Softarex designed and modeled a prototype of an automated defect-detection system combining high-resolution cameras with computer vision algorithms for real-time inspection. The setup captures surface data during component rotation and processes it within 5 seconds to identify defects without slowing down production.

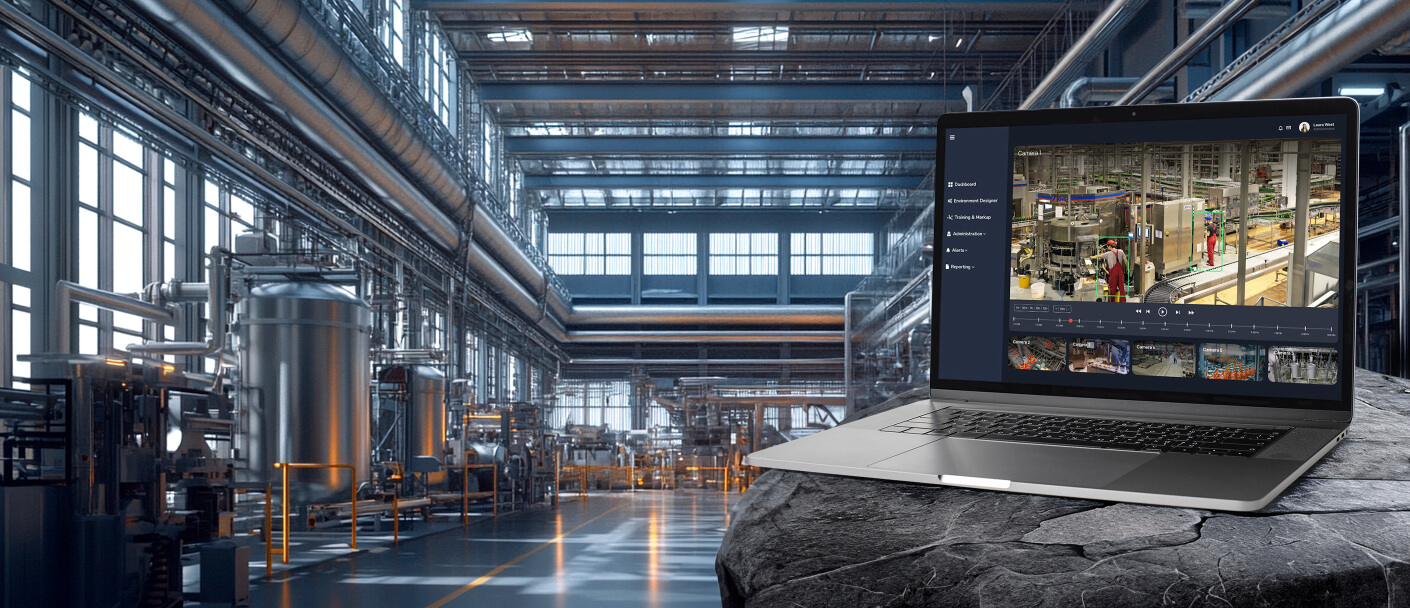

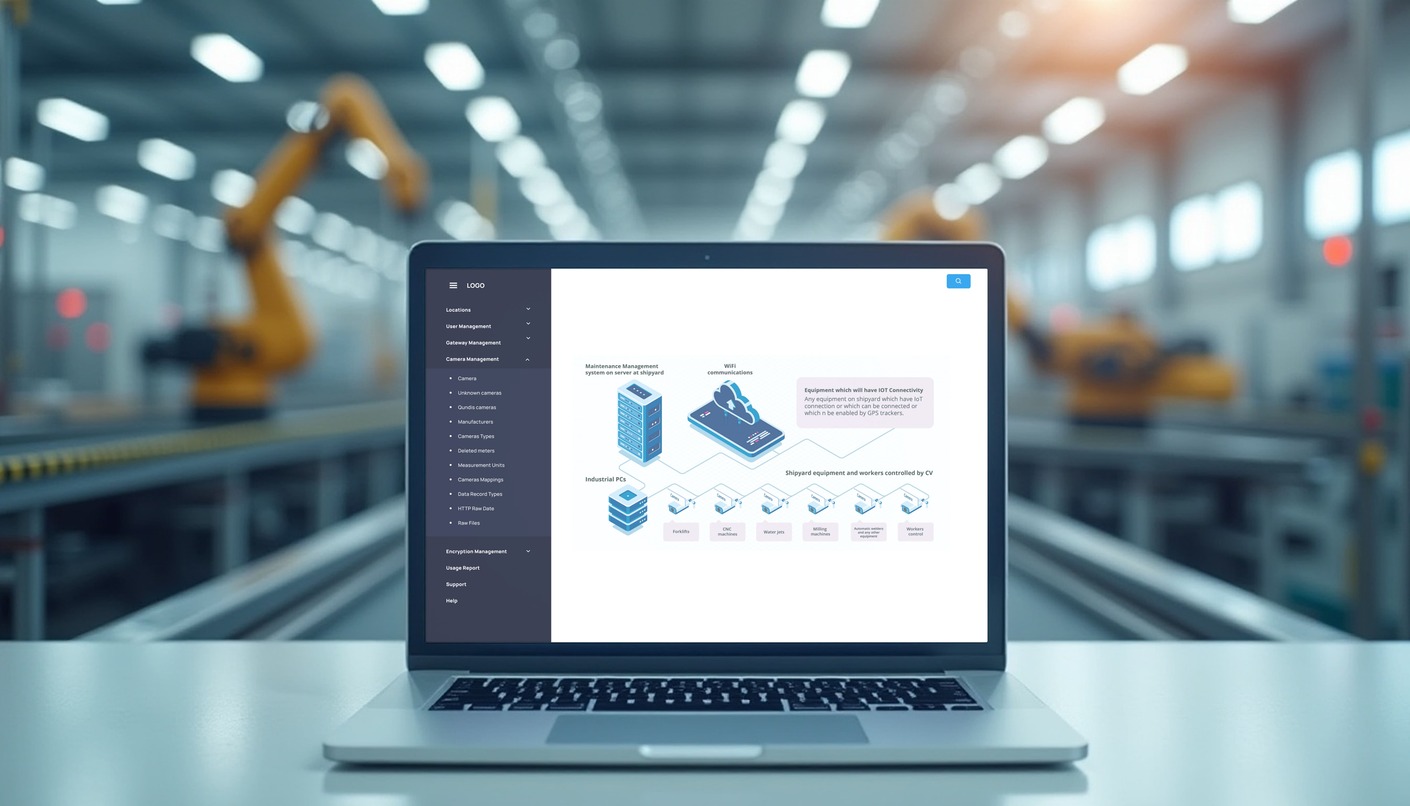

Captured data is transmitted to a custom web application operating on a local computer configured as an on-premise server running Linux. The system architecture includes a Java and Python backend and a React-based frontend accessible across the local network, allowing operators to review inspection results from multiple connected devices.

At the prototype stage, the solution focused on two defect categories:

- absence-related defects such as missing balls, missing cage rivets and missing ring material;

- localized surface defects including cavities, dents, nicks and black spots

- Automated scanning system for high-speed data acquisition and processing, enabling fast and accurate defect detection.

- Image-processing modules that analyze camera input in real time, classify defects and store annotated data for traceability.

- User interface that provides easy control of the scanning process and visual displays of detected defects for quick operator assessment.

- Standalone scanning station designed as a dedicated camera-based inspection point capable of identifying surface abnormalities directly from video streams.

Project’s results

- The Softarex team built a production-ready PoC for in-line deployment.

- Designed and prototyped a standalone robotic scanning station for automated bearing inspection.

- Confirmed viability of computer vision for 100% testing at production-level speed in high-load industrial environments.

- Ensured reliable inspection across flat faces, curved surfaces and internal diameters, including hard-to-reach areas.

- Achieved detection of cavities, laps, cracks, indentations, corrosion, black spots, burrs, discoloration, pattern defects, scratches, smears and rust spots across multiple product types.

- Reached a processing time of ~26 ms per image and a throughput of 30+ images per second, with full analysis of one ring completed in 3–5 seconds.

- Prepared full IP documentation to support the customer’s filing strategy.

- Provided consulting on inspection methodology and automation to improve the customer’s QC process.

Technical challenges

Selected Projects Overview

Get in touch with Softarex’s team

Have questions about your future project? Feel free to contact our team.