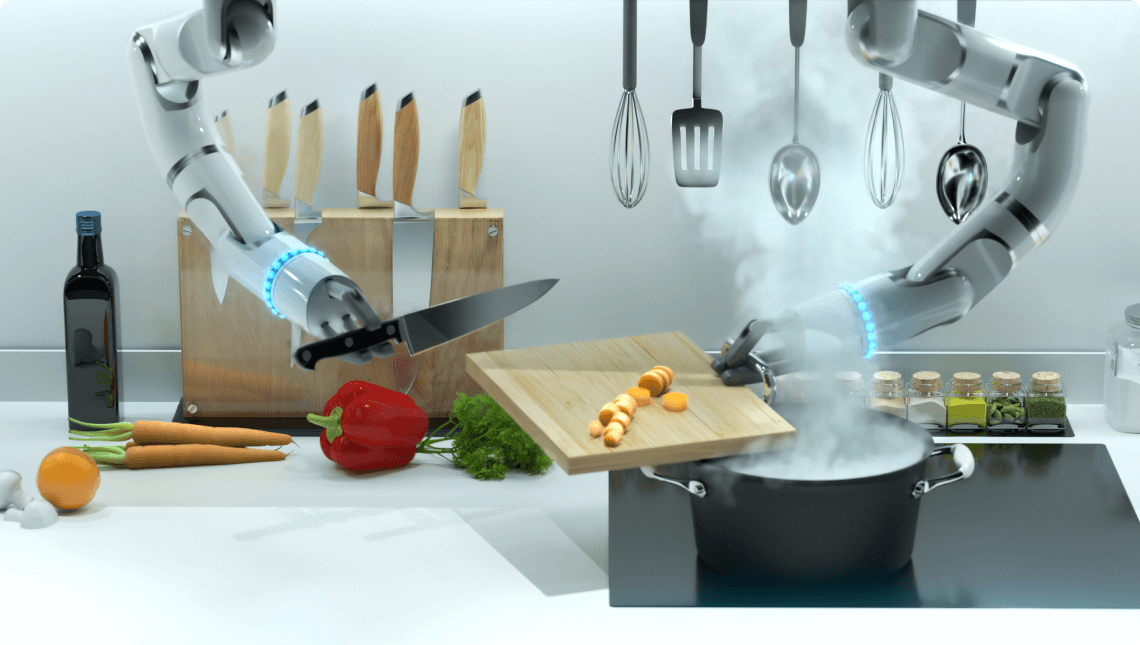

Automation is not just transforming supply chain, inventory, and energy management; it’s also reshaping the kitchen. Robots are stepping in to assist with food preparation and cooking, becoming integral to the culinary process. These “co-bots” work alongside human employees, requiring supervision and collaboration to ensure tasks are completed efficiently.

Within the kitchen, robotic arms are taking over monotonous, labor-intensive, and hazardous tasks. For example, robots manage fryers, handle hot ovens, and process dough on production lines. Domino’s, for instance, employs robotic dough stretchers, while Chipotle’s Autocado concept automates avocado preparation, reducing the risk of cuts and repetitive strain injuries.

Collaborative Automation: Aiming for Smoother Operations

By working closely with staff to identify tasks that could benefit from automation, restaurants aim to make daily operations smoother and less complicated, whether it’s on the digital make-line or other tasks in the back of the house. For example, Chipotle is testing Chippy, an autonomous kitchen assistant that uses AI to make and season tortilla chips. Also, Chipotle’s new technology-enabled makeline for salads and bowls uses robotics to boost workforce potential. CEO Brian Niccol believes that innovations like the digital makeline and Autocado can elevate the overall dining experience by ensuring timely, accurate, and delicious food preparation.

Domino’s has embraced automation in their dough production line. Their new $50 million manufacturing plant in Indiana uses machines to blend ingredients, and direct dough movement, significantly reducing manual intervention. A set of cameras continuously monitors the dough balls to prevent sticking and ensure their correct placement on trays. An automated system is also in place to label each tray for inventory management purposes. By automating dough ball production, Domino’s can increase efficiency, reduce labor costs, and gain economies of scale, showcasing how investment in advanced equipment can lead to substantial operational benefits.

Kitchen automation equipment integrates seamlessly with existing infrastructure, enabling diverse operations to be automated, whether on specific equipment or across different units. One example is an automated robotic system that integrates with soda fountain machines to streamline beverage preparation. This system transforms beverage service by selecting cups, printing and applying labels, dispensing ice and beverages with precision, and capping the drink – all orchestrated by a robotic arm to ensure accuracy and efficiency. Once the drink is prepared, it’s placed in the ready area, signaling staff via an LCD display that the order is complete.

Kernel: A New Frontier in Restaurant Automation

Unlike other chains that have retrofitted their kitchens for robots, Kernel, founded by Chipotle Mexican Grill founder Steve Ells, stands out by designing its space for robots from the ground up. Food is cooked off-site by chefs, delivered hourly by bike couriers, and heated by robots. With only three kitchen staff members and one greeter, Kernel’s streamlined operations are incredibly efficient. Customer orders go straight to a robotic arm that handles food prep, while a programmed toaster and conveyor belts complete the process. Employees add final touches, package orders, and place them in cubbies for easy pickup.

The setup is fast and accurate; allows paying employees more and cuts down on food waste from human errors during ordering or cooking. Since opening just over six months ago, Kernel has had minimal staff turnover, which is unusual in the industry. This success is due to involving team members in developing the concept. At the end of each day, staff meet to provide feedback and suggest improvements, which empowers them and enhances restaurant operations.

The Future of Automation in QSRs: Balancing Technology and Human Input

Top QSRs are turning to robotics to improve efficiency and address labor shortages in an industry where jobs are often low-paying and physically demanding. For some, culinary robots are perfectly positioned to solve a specific problem for their kitchen operations. For example, robots working alongside humans can automate a wide range of tasks, such as frying, tossing, flipping burgers, slicing, peeling avocados, or even dispensing beverages.

But while robots are now good at certain tasks, such as frying French fries, they are not yet capable of managing entire cooking processes. Concerns about automation replacing workers persist, but major food chains like Yum! Brands emphasize that employees remain essential, and that technology should complement rather than replace their roles. Human input is critical to fine-tuning the technology and ensuring it works effectively, underscoring the continued need for human oversight and feedback. In addition, robotics could lead to new job opportunities in areas such as development, maintenance, and operations, potentially shifting some roles to more skilled positions.

The focus now is not only on redefining how robots and humans work together, but also on ensuring that employees have a voice in shaping this new dynamic. This collaborative approach may be the key to balancing technology and human labor as the fast food industry evolves.

To explore comprehensive strategies for implementing artificial intelligence solutions in restaurant operations, download our detailed eBook, Transform Your Restaurant with AI-Powered Solutions. This resource examines practical AI applications, implementation frameworks, and emerging technologies that are revolutionizing restaurant management, customer experience, and operational efficiency.