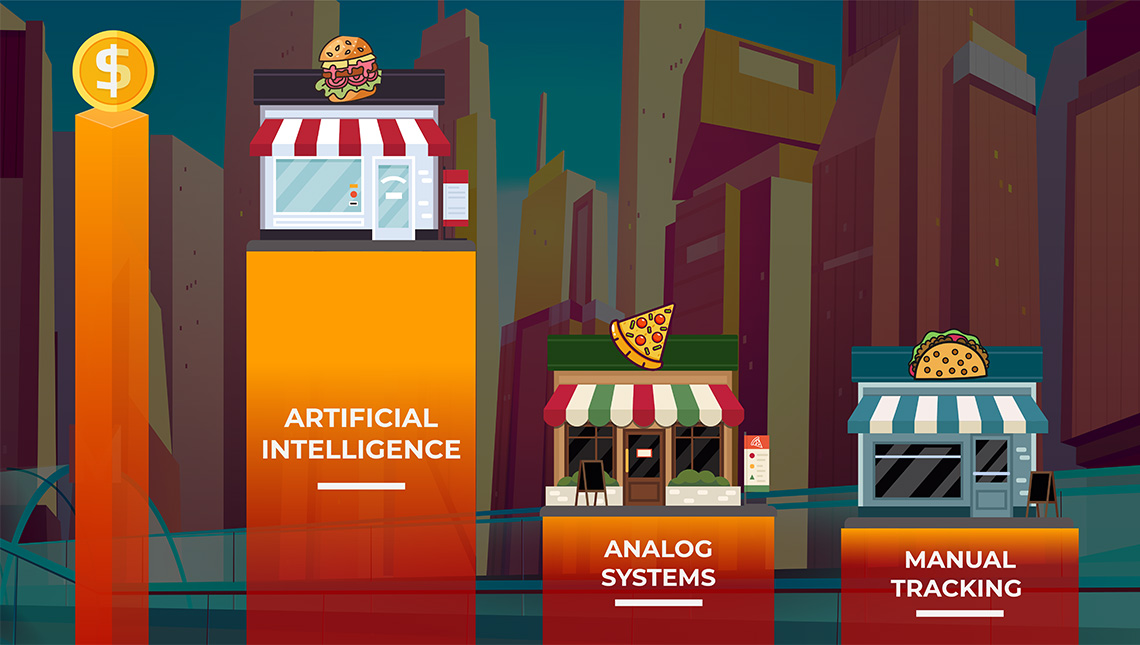

Optimizing supply chain management and back-of-house operations has never been more crucial for improving the bottom line for players in the QSR industry. With the recent expansion of restaurant management technologies, including AI, smart cameras, IoT frameworks, analytics platforms, predictive tools, and robot chefs, businesses now have a diverse toolkit to drive financial performance and operational efficiency. These technologies can be adapted to businesses of all sizes: from individual restaurants to franchises and large enterprises.

In this article series, we will cover the hottest trends and examples of how intelligent technologies can enhance restaurant performance, leading to improved food quality, reduced wait times, and a more harmonious kitchen environment.

Automating Order Management

The old-fashioned way of managing orders relies too heavily on manual entry and is prone to error, especially during busy periods. This slows down order fulfillment, resulting in missed revenue opportunities and upset customers. Using AI to automate supplier order entry not only makes processes smoother but also helps build a smarter and more eco-friendly food system.

AI solutions can help automate restaurant-suppliers order management, mitigating the challenges of manual processes. App-based ordering tools gather and process orders from various communication channels like voicemail, SMS, WhatsApp, or email, and convert them into a standardized digital format. These orders then flow into a supplier’s existing ERP system in real time.

Both suppliers and restaurants receive instant confirmations, ensuring a smooth, error-free order journey. In addition, all of a company’s orders are consolidated and managed in a single central location, reducing waste and optimizing inventory. Suppliers also receive access to structured data and flexible delivery options, while gaining a single view of customer data for insights into behavior across all channels.

Softwarex implemented these principles by developing a Restaurant Inventory Management System for a growing chain. This system enabled the client to streamline operations, reduce waste, and maximise profits.

Enhancing Order Accuracy with Computer Vision-based Technology

In the wake of the pandemic, the restaurant industry has realized the critical significance of technology and its pivotal role in enhancing both customer and employee experiences.

Yum! Brands, for example, has engaged in numerous strategic technology partnerships to integrate technology into every area of its business. They aim to make it easier for customers and employees to interact with the company while increasing their own and their franchisees’ profitability.

Out of all areas ordering has shown to be the one needing innovation the most. The pandemic instilled the habit of ordering online instead of dining in. This led to a drastic increase in drive-thru orders and consequently created various operational challenges for QSRs, particularly in ensuring order accuracy.

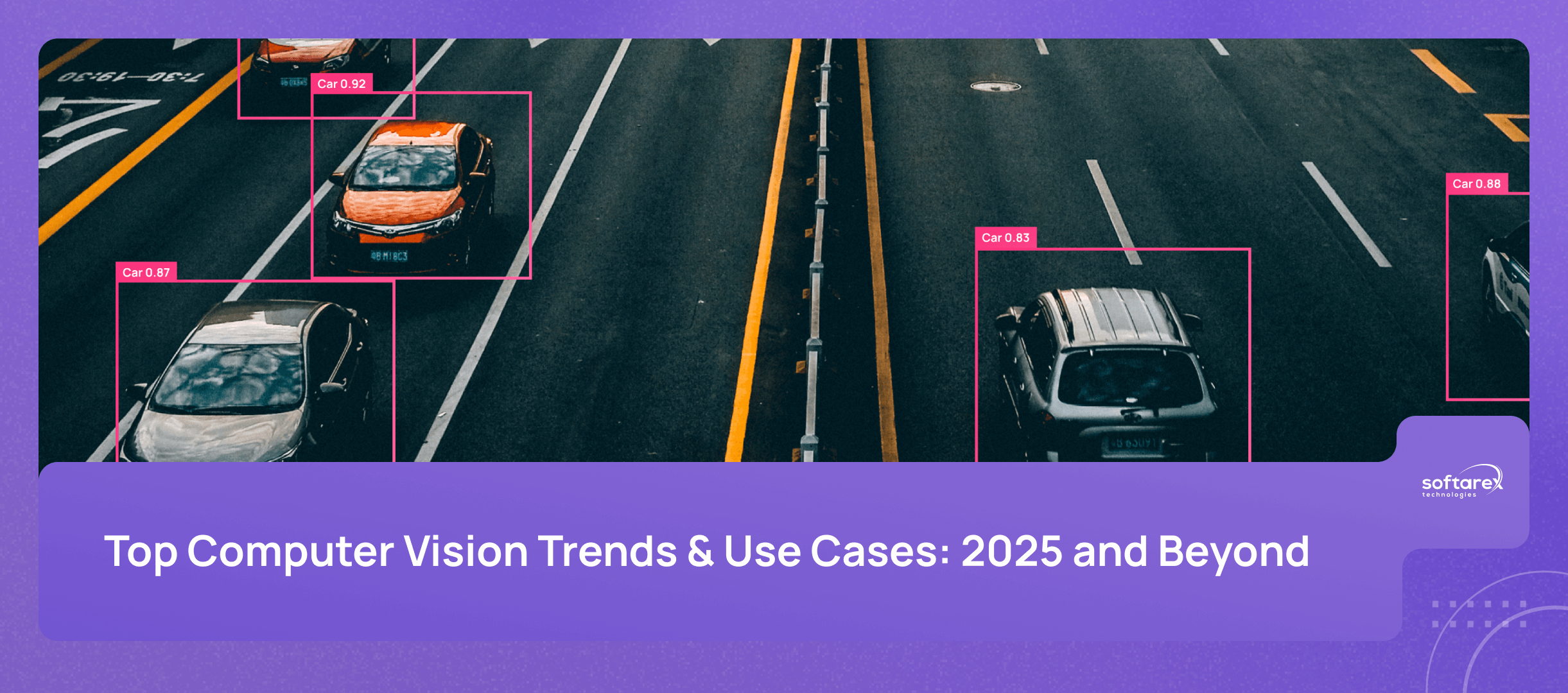

Luckily, technology can help confirm order accuracy in real-time and notify employees of necessary corrections. Computer vision, for example, can support employees in restaurant kitchens by ensuring that orders are prepared correctly. And this is just the tip of the iceberg.

Using overhead cameras powered by Computer Vision, restaurants can monitor kitchen activity in real time. A real-life example of this is the AI Kitchen Management System developed by Softarex for a major US quick service restaurant brand. Using video analytics, it measures ingredient weight and monitors kitchen workflows with high precision, ensuring that every dish meets brand standards. Such a system identifies items being prepared in the kitchen and then sends real-time alerts to line workers for corrections, ensuring accuracy down to the ingredient level. But that’s not even half of its capabilities.

It also provides real-time preparation schedules based on dynamic demand forecasting. The system monitors store traffic (both in-store and drive-thru guests), POS software, and available ready-to-sale inventory and provides employees with recommendations and inaccuracy alerts via touch screens. That way restaurant crews know what and how much they need to cook, which helps reduce overhead costs and food waste. Additionally, managers on the back end can remotely monitor operations at one or more restaurants.

Behind the scenes, such a computer vision solution uses proprietary data augmentation methods to train AI algorithms, which facilitates scalability and adaptability. And to ensure robustness, the system incorporates simulation data from various kitchen scenarios. Privacy concerns are addressed through an offline-first-edge AI solution, with control over customer data and compliance with privacy policies. This approach helps restaurant teams improve efficiency by ensuring order accuracy, benefiting both employees and customers.

Monitoring the Safety of Food Supply Chain

Managing perishable items such as fresh produce and meats in the food supply chain presents unique challenges for restaurants. To ensure they are safe for consumption, it is necessary to carefully manage stocks and adhere to strict storage conditions. Fortunately, technology can enhance food safety programs. And industry leaders are already recognizing its potential in managing the supply chain.

For example, Chipotle was one of the first among major restaurant chains to implement radio frequency identification (RFID) case labels for ingredient tracking. Laurie Schalow, Chipotle’s Chief Corporate Affairs and Food Safety Officer, says they “see this innovation as the next evolution of traceability and food safety”.

RFID and other technologies track products in real time, enabling rapid response to food safety and quality concerns. When ingredients arrive at restaurants with RFID-enabled case labels, integrated RFID readers automatically scan them in a matter of seconds and even without requiring direct line-of-sight, which significantly reduces human error.

Thanks to this automation, restaurants always have the most accurate inventory data at their fingertips, which is critical for forecasting and replenishment. And with easy access to expiration dates via RFID, both QSRs and their supply partners can efficiently manage product inventory by identifying items that are about to expire.

In addition, IoT asset tracking improves product integrity and safety by monitoring temperature, humidity and chemical compounds throughout distribution. Sensors placed in vehicles or on packaging can promptly alert professionals to any abnormalities, enabling them to take immediate action to prevent contamination or spoilage. And by collecting data on temperature and humidity fluctuations, companies can anticipate potential losses and take preventative steps to minimize the risk of product recalls and ensure product quality.

This is just the beginning of our exploration into the ways technology can transform your business and society. There’s a lot more to cover, and we’ll delve deeper into this topic in future articles. Stay tuned for the next installment in our series on game-changing restaurant technology.

To explore comprehensive strategies for implementing artificial intelligence solutions in restaurant operations, download our detailed eBook, Transform Your Restaurant with AI-Powered Solutions. This resource examines practical AI applications, implementation frameworks, and emerging technologies that are revolutionizing restaurant management, customer experience, and operational efficiency.