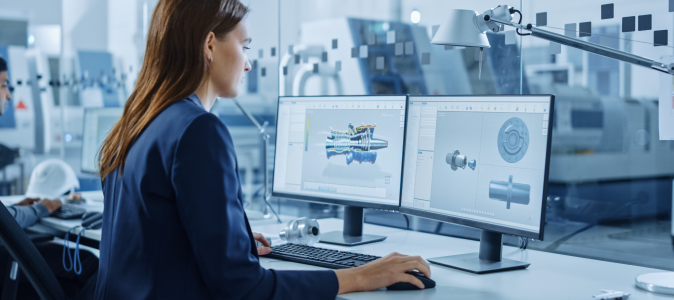

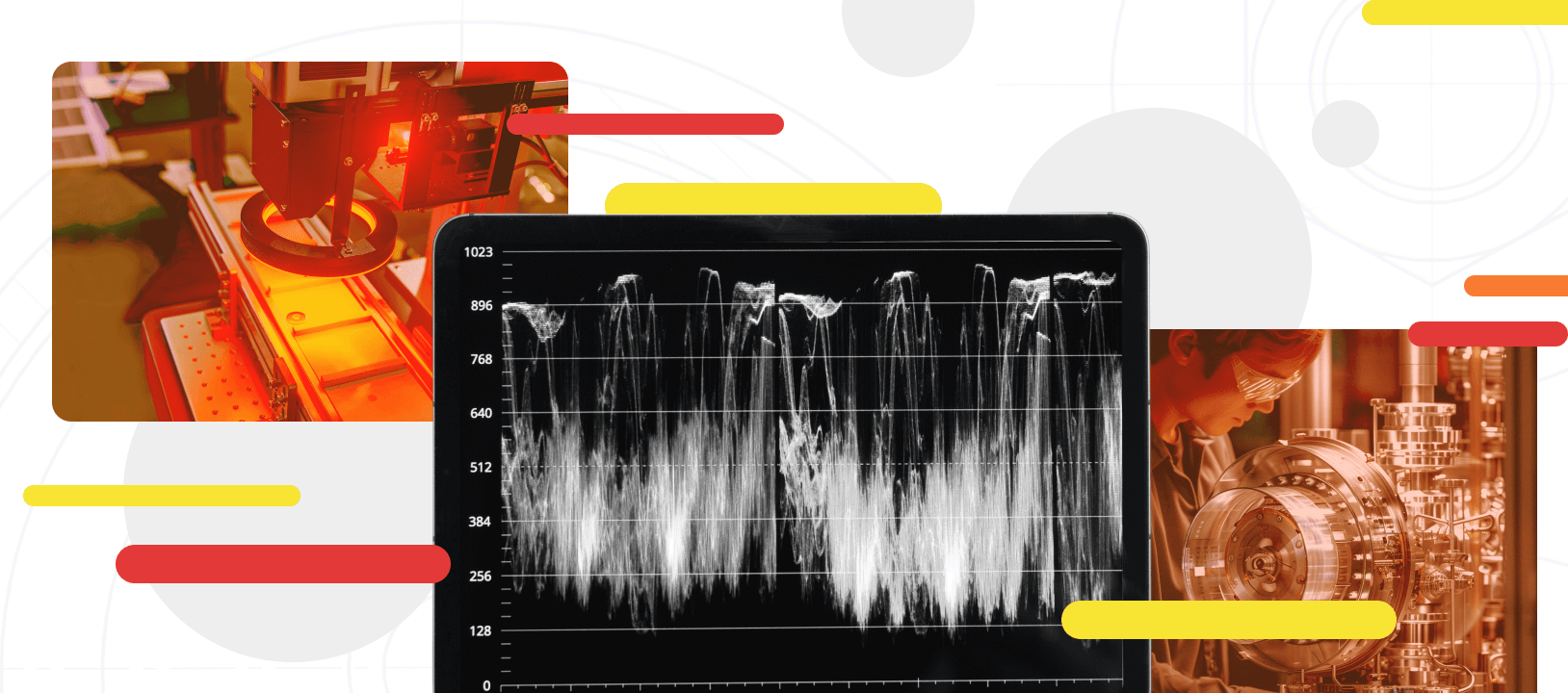

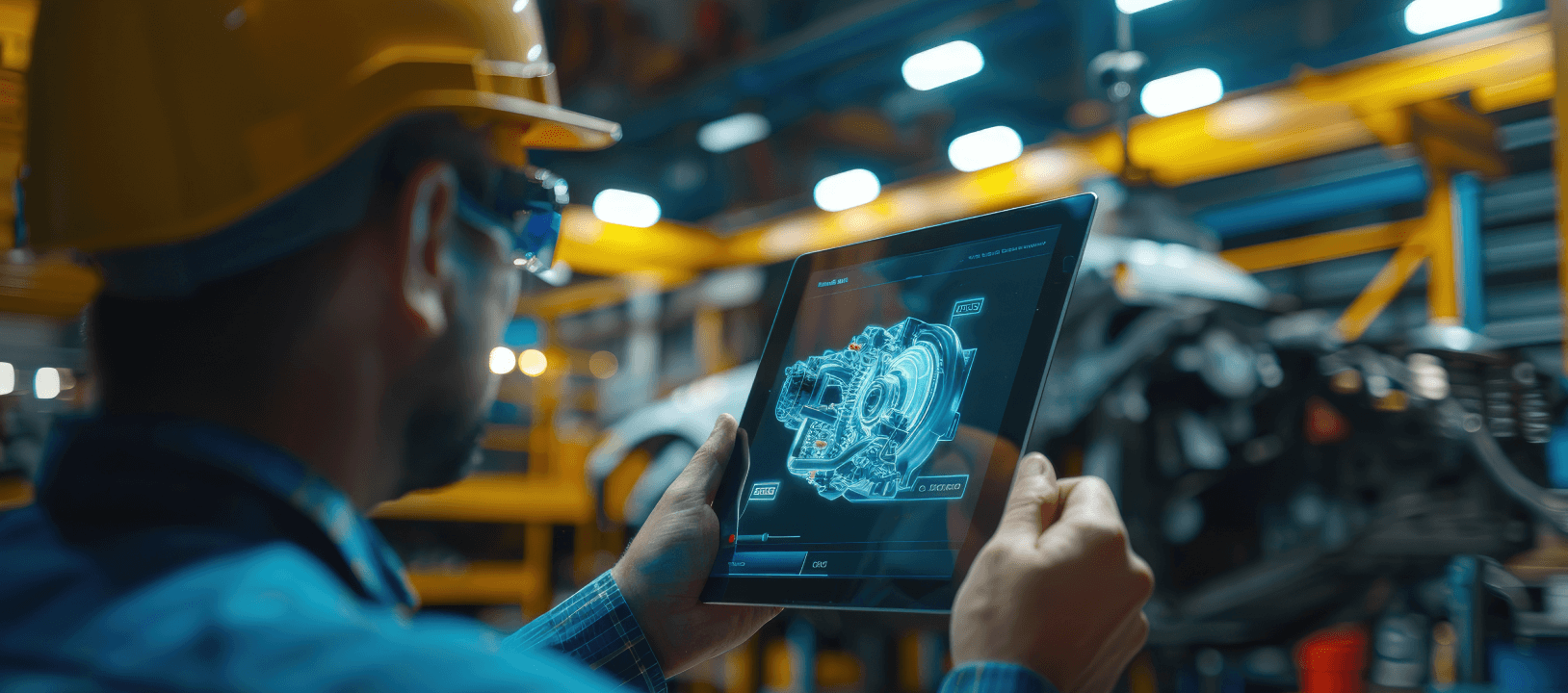

Softarex develops custom software for manufacturing and energy sectors, utilizing computer vision, IoT, cloud computing, and data science. Our solutions enhance transparency, improve decision-making, and optimize production workflows, supporting the progress of Industry 4.0 and driving operational efficiency in production environments.

Get guaranteed results and maximise business value

Robotics is the new black in the world of digital transformation.Technologies

AI in Manufacturing

- Predictive maintenance

- Quality control

- Factory floor management

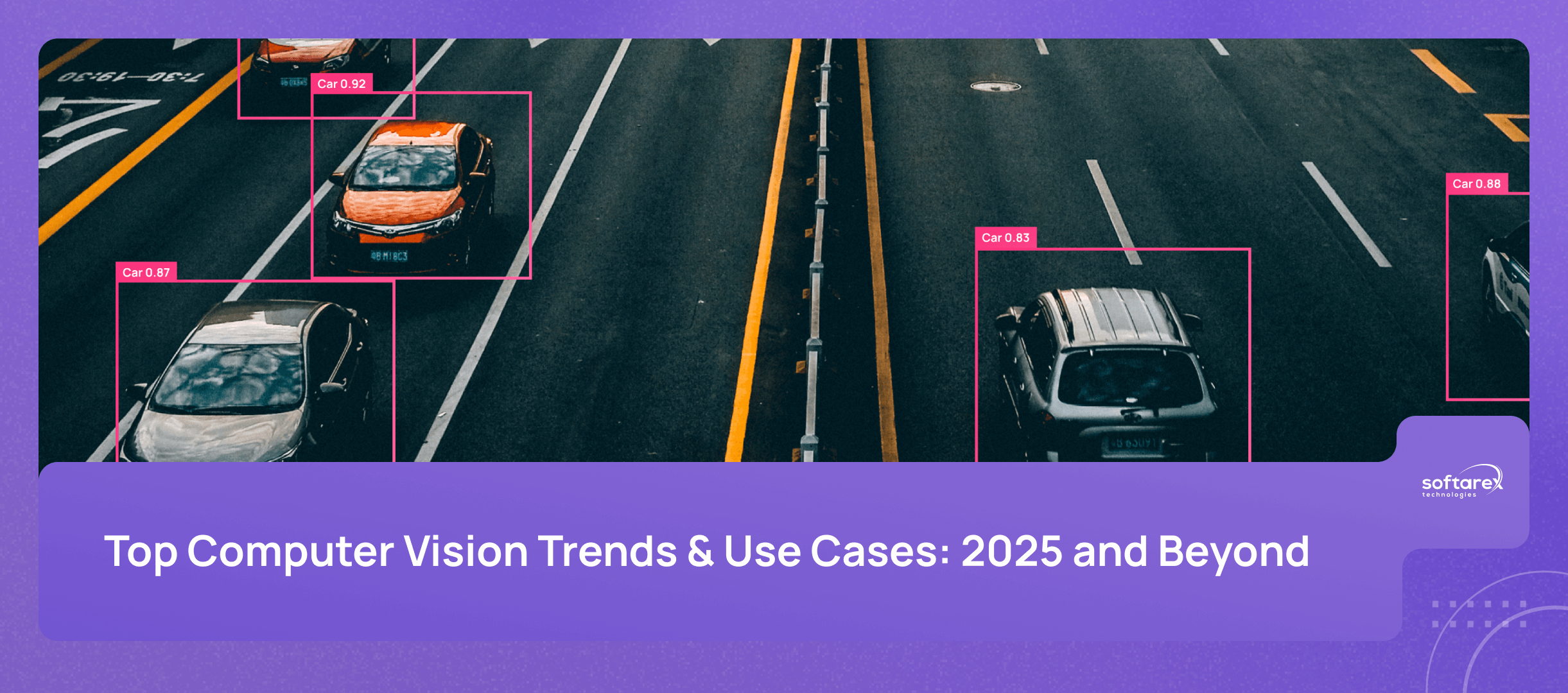

Computer Vision in Manufacturing

- Quality control

- Product inspection

- Robotic guidance

- Defect detection

Robotics in Manufacturing

- Assembly line automation

- Warehouse management automation

IoT in Manufacturing

- Equipment maintenance automation

- Production process management

- Supply chain management

AI in Manufacturing

- Predictive maintenance

- Quality control

- Factory floor management

Computer Vision in Manufacturing

- Quality control

- Product inspection

- Robotic guidance

- Defect detection

Robotics in Manufacturing

- Assembly line automation

- Warehouse management automation

IoT in Manufacturing

- Equipment maintenance automation

- Production process management

- Supply chain management

Our experts

We are experts in software and hardware engineering. By using and combining cutting edge technologies, we create unique solutions that transform industries.

Sergii

System Architect and Delivery Manager

My main responsibility as a Delivery Manager is to make sure that a product is delivered on time and within budget. To achieve that, I seek to create an encouraging environment for the team, where everyone can improve their skills, feel appreciated and, thus, produce greater value.

The use of Agile tools and techniques helps me organize the teamwork more effectively and transparently. Throughout my career, I have also been actively architecting, designing, and implementing software solutions — mostly web and desktop applications — for the Healthcare, Manufacturing & Energy industries that help companies and organizations streamline day-to-day business operations.

Andrey

Senior Software Engineer

During my 17 years of experience, I have gained expertise in SoC firmware across different architectures, embedded Linux, PLCs, Android development, data processing on the backend using Java and C++, web development, and desktop development on Windows and Linux. I have worked on projects in fields such as Energy and Utilities, Smart Home, Public Transport, Healthcare, E-commerce, Learning, and SaaS.

As a software engineer, I conduct research, design software architecture, create and maintain project documentation, and implement product features. While working on projects with active development cycles, I stay updated on new changes to the apps we use so that we can take advantage of new language features and tools to improve our development.