- From Routine Repairs to Real-Time Insights

- Key Technologies Powering Smarter Maintenance

- Business Performance Impact of Predictive Maintenance

- Predictive Maintenance in Manufacturing: Real-World Applications

- Addressing Key Challenges in Predictive Maintenance Rollout

- The Future of Predictive Maintenance in Manufacturing

- Pathway to Future Growth

Building on our earlier discussion of predictive analytics in manufacturing, where we explored the power of data to transform production processes, we now turn to predictive maintenance. This advanced application evolves the role of analytics from understanding production patterns to creating an intelligent system that safeguards the health of machinery and ensures operational reliability.

From Routine Repairs to Real-Time Insights

Maintenance strategies have evolved dramatically with the integration of Internet of Things (IoT) and real-time data analytics, transforming how industries approach equipment reliability. While both predictive maintenance and preventive maintenance aim to reduce downtime, their methodologies and effectiveness differ significantly in the age of smart manufacturing.

Preventive maintenance relies on scheduled, routine inspections and replacements based on predetermined time intervals or usage metrics. In contrast, predictive maintenance leverages IoT sensors, computer vision, real-time data, and machine learning algorithms to detect potential failures before they occur.

This distinction has become crucial as recent data from Siemens reveals that unplanned downtime costs Fortune Global 500 companies approximately $1.5 trillion annually, representing 11% of their yearly turnover.

The key difference lies in how each method handles maintenance decisions. Preventive maintenance follows a fixed schedule, regardless of the equipment’s actual condition – often resulting in unnecessary upkeep or, worse, missed issues. In contrast, predictive maintenance relies on continuous monitoring through IoT sensors, analyzing real-time performance data to determine exactly when maintenance is needed.

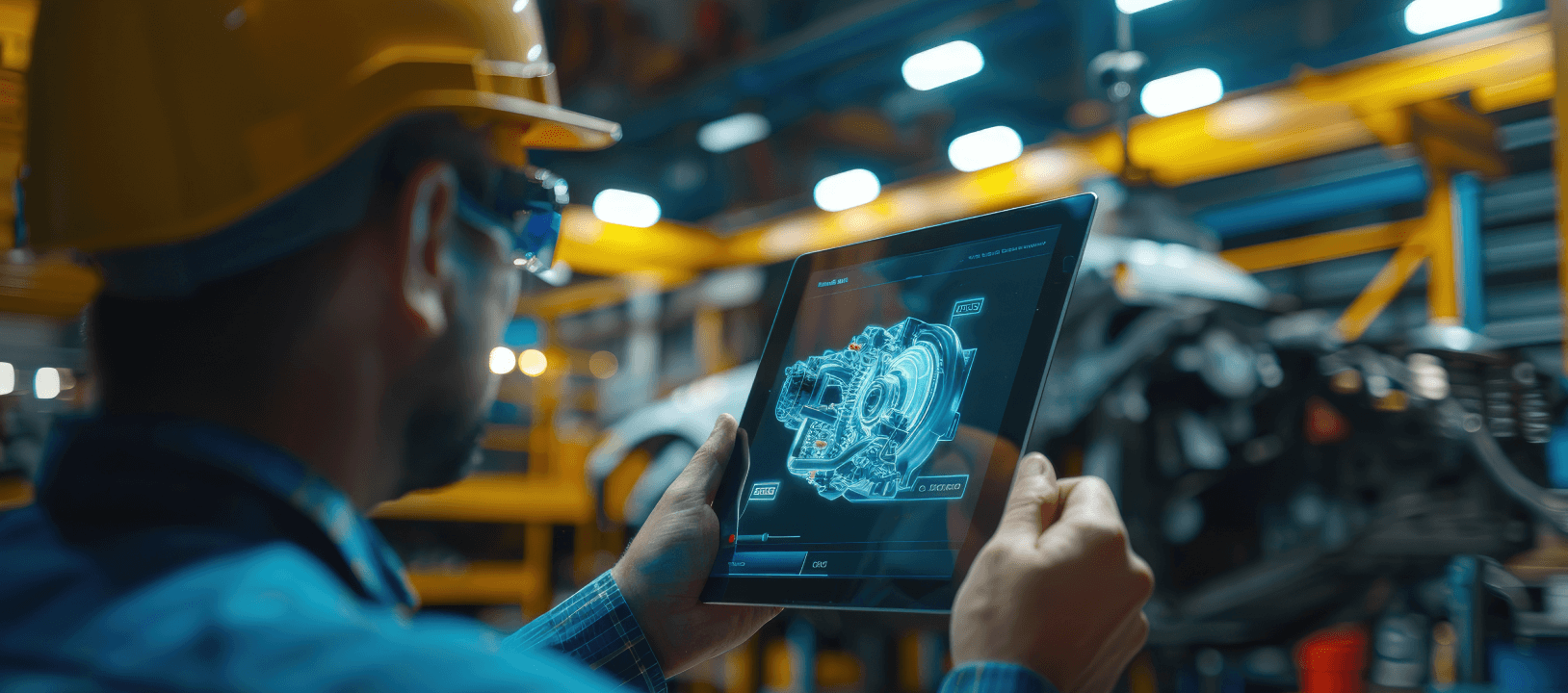

That’s the principle behind our custom Equipment Maintenance Software. By combining IoT, computer vision, and neural networks, it continuously monitors machinery, delivering insights that help detect potential failures before they happen.

This intelligent system empowers organizations to shift from reactive or routine maintenance to a predictive model – cutting costs, preventing downtime, and improving equipment reliability and efficiency.

Key Technologies Powering Smarter Maintenance

Despite rapid advances in technology, many manufacturing facilities still rely on outdated maintenance approaches. The transition to modern predictive maintenance systems has been slower than expected, with a recent survey revealing that 69% of respondents found their investments in operational technology have not met expectations. This is often due to the selection of inappropriate AI and IoT systems or poor integration strategies, highlighting the critical importance of understanding core technologies before making significant investments in predictive maintenance solutions.

The foundation of effective predictive maintenance relies on several key technologies:

Data Collection and Integration

- IoT sensors continuously monitor equipment performance and operating conditions

- Centralized data management systems collect and organize large amounts of information

- Integration with existing systems ensures comprehensive data collection across operations

Advanced analytics and AI

- Machine learning algorithms identify patterns in operational data to predict potential failures.

- Predictive analytics use historical data to predict maintenance needs

- Digital twins create virtual replicas of equipment for testing and simulation

- Computer vision systems provide visual inspection and monitoring

These technologies work together to overcome traditional maintenance limitations such as manual data collection and discrete support systems. Instead of relying on periodic inspections or manufacturer recommendations, advanced predictive maintenance systems provide real-time insights and automated decision-making capabilities.

Softarex put this into practice with a Production Monitoring System, helping a manufacturer boost efficiency and cut downtime.

Business Performance Impact of Predictive Maintenance

According to recent industry data, unplanned downtime costs industrial manufacturers approximately $50 billion annually, and more than 80% of companies underestimate their actual downtime costs. However, organizations that have implemented predictive maintenance strategies have demonstrated significant improvements in operational efficiency.

The 2020 McKinsey report highlights that the implementation of predictive maintenance can increase asset productivity by up to 20%, while reducing overall maintenance costs by 10%. These efficiency gains are achieved through the strategic deployment of smart sensors and real-time monitoring systems, which detect early warning signs of potential failures. For example, sensors can identify subtle changes in equipment vibration, temperature and pressure levels before they escalate into critical issues, allowing maintenance teams to intervene at the optimal time.

The financial benefits go beyond direct maintenance costs. Predictive maintenance helps companies avoid the cascading negative effects of unexpected equipment failures, including lost production that directly impacts the bottom line, increased labor costs due to emergency repairs and overtime, loss of customer confidence due to delayed deliveries, and potential damage to the company’s reputation for reliability and efficiency.

Most importantly, predictive maintenance strategies have demonstrated the ability to reduce equipment downtime by up to 50% compared to traditional maintenance approaches, without the downside of over-maintenance. This improvement is achieved through precise, data-driven maintenance scheduling that maximizes equipment life while minimizing unnecessary interventions.

Predictive Maintenance in Manufacturing: Real-World Applications

By looking at real-world examples of predictive maintenance, we can see how this technology can be effective in addressing critical challenges such as downtime and maintenance costs.

A packaging and paper manufacturer implemented a health monitoring and predictive maintenance system on 60 complex machines to reduce breakdowns and material waste. The system uses sensors to monitor vibration, noise, and temperature data from extrusion and printing systems, generating 7 GB of data daily. Machine learning models, including bagged decision trees, analyze this data to predict failures before they occur. The implementation saved over €50,000 annually on just eight machines, with a working prototype completed in six months. The system continues to run in production, with additional savings expected as more machines are integrated.

A food and beverage manufacturer implemented predictive maintenance on their air compression systems used for packaging, cutting, shaping, and cleaning. The system uses vibration sensors to monitor compressor health, flow sensors to detect pressure fluctuations and leaks, and temperature sensors to prevent overheating. The implementation prevented approx. $150,000 in downtime costs and achieved $50,000 in energy savings through early detection of failures and dynamic control.

Beyond line machines and air compression systems, predictive maintenance system monitors the condition of other types of equipment using specialized sensors:

- Industrial robots use joint sensors and motor feedback to detect movement irregularities and torque issues

- Conveyor belts use vibration and acoustic sensors to identify misalignments and component wear

- HVAC systems use temperature, humidity, and flow sensors to monitor efficiency and blockages

- Hydraulic systems use pressure, fluid, and temperature sensors to detect leaks and component wear

- Gearboxes use vibration monitoring to detect wear, misalignment, and lubrication problems

Addressing Key Challenges in Predictive Maintenance Rollout

While predictive maintenance offers significant benefits, organizations face several key implementation challenges. The primary obstacles can be categorized into four critical areas.

First, financial considerations present a significant barrier, as predictive maintenance implementation requires substantial initial investment in sensors, data storage infrastructure, and analytics capabilities. Companies must carefully evaluate their return on investment (ROI), taking into account factors such as equipment complexity and required expertise.

Data quality and management is another challenge. The effectiveness of predictive maintenance systems depends heavily on the availability and accuracy of operational data. Organizations often struggle with insufficient historical data, especially in the early stages of implementation. In addition, sensor reliability issues such as downtime, degradation, and noise, can lead to inaccurate predictions or false alarms if not properly addressed.

Integration complexity is a third major challenge. Companies face technical difficulties when integrating predictive maintenance systems into their existing operational infrastructure. This integration often requires coordination between IT teams and maintenance specialists, making the implementation process more complex than traditional maintenance systems.

Finally, organizational and human factors play a critical role. Despite advances in automation, maintenance activities still rely heavily on human expertise and intervention. The transition to predictive maintenance requires not only technological adaptation, but also significant organizational change management and workforce training to ensure effective use of the system.

The Future of Predictive Maintenance in Manufacturing

The future of predictive maintenance is remarkably promising, with market projections predicting growth to $107.3 billion by 2033 at a CAGR of 28.5%. As AI and machine learning technologies advance, the industry is moving toward smarter systems where machines don’t just predict failures – they autonomously schedule and perform their own repairs. The integration of digital twins makes this future even more exciting, enabling real-time decision-making that significantly improves production efficiency.

The industry is already experiencing this transformation, with the solutions segment capturing 83% of the market share. Companies are increasingly investing in comprehensive services, from system integration and maintenance to specialized training, making predictive maintenance an integral part of their enterprise systems. This shift reflects a broader trend toward data-driven decision making, where companies are leveraging predictive maintenance as part of their IIoT strategy to stay competitive.

Perhaps most importantly, predictive maintenance is becoming a critical tool for manufacturing sustainability. Advanced monitoring and analytics are helping companies reduce energy consumption, minimize material waste, extend asset life, and create safer workplaces. As these technologies continue to evolve, predictive maintenance will move from a competitive advantage to an essential requirement for modern manufacturing operations.

Pathway to Future Growth

The move to predictive maintenance represents a fundamental shift in the way manufacturers approach operational excellence. Beyond the immediate operational benefits, predictive maintenance transforms organizational culture by freeing up time for data-driven problem solving and fostering greater confidence in decision-making processes. The impact of the technology extends throughout the operational chain, from reducing inventory carrying costs to preventing equipment failures that could pose safety risks by detecting potential malfunctions early, monitoring critical safety parameters, and ensuring that equipment is operating within design specifications.

As manufacturing evolves, those who embrace predictive maintenance not only gain improved efficiency, but a sustainable competitive advantage through clearer performance metrics, enhanced accountability, and streamlined maintenance processes. For manufacturers weighing their options, the evidence is clear: predictive maintenance is not just another technology upgrade – it’s an essential investment in operational resilience and future growth.