Large facilities such as shipyards, automotive manufacturing plants, and aircraft maintenance hangars, have a significant amount of various equipment and machinery: forklifts, production machines, critical support equipment, and IoT devices. And all tasks related to their maintenance and monitoring are usually done manually, which is extremely time-consuming and labor-intensive.

Therefore, they are seeking digital solutions that would help automate all equipment tracking and maintenance tasks, provide real-time insight into machinery condition, and keep staff members informed about any urgent issues.

To help our Client, a major manufacturing company, to tackle this challenge, we have developed a custom cloud-based Equipment Maintenance Management System (EMMS)* for real-time equipment monitoring and maintenance planning.

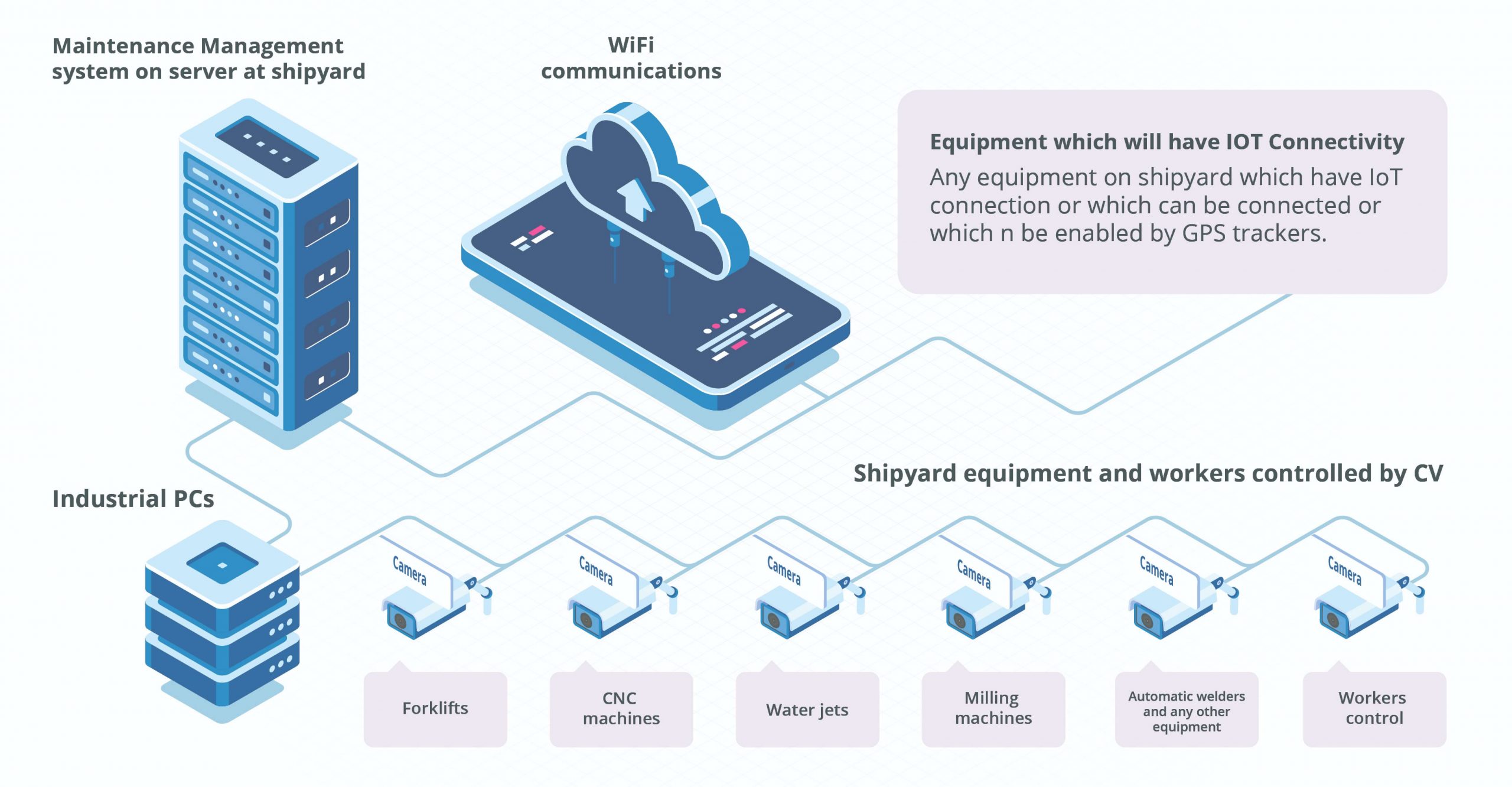

That’s how it works: EMMS collects data from video cameras, IoT devices, and GPS trackers used to monitor the equipment in real time. Then, using computer vision technology and neural networks, the system processes the obtained information: it recognizes individual machines in the footage by visual markers and determines their run time and condition. And finally, it creates detailed reports showing what maintenance activities should be carried out and based on that sends commands to IoT-powered equipment, creates and assigns tasks to the responsible staff members, and generates voice messages and notifications.

Equipment Maintenance Management System is a distributed system. Its components are deployed on local servers of a facility and on industrial PCs located in places where video cameras are used. The local server component of EMMS provides functionality for real-time equipment monitoring, control, and maintenance management. The part located on industrial PCs is used for visual tracking of different equipment and controlling its usage.

Additionally, EMMS can be used to monitor and analyze staff availability, movements, activity, and behavior, as well as count the number of employees in each zone in real time using hallway view cameras and neural networks. It can help greatly optimize workforce allocation, increase productivity, and facilitate more data-driven maintenance planning decisions.

In addition to the system, Softarex has built a web-based end-user application compatible with iOS and Android tablets. The app is designed to improve communication between staff members involved in the equipment maintenance process.

The structure of the EMMS components is presented below.

* This is a custom solution we have developed for the specific needs of a particular Client. Does it look like it may be a good fit for you? Contact us, and we’ll build a custom solution tailored specifically to your business needs.

Our Equipment Maintenance Management System has brought the following benefits to our Customer’s business: